Chiller doors

The chiller doors are intended for the rooms with the temperatures ranging from 0 to +5 degrees Celsius. The doors can be made of stainless steel, coated steel or painted according to RAL palette. It is also possible to manufacture the mixed doors, where the doorframe is made of stainless steel, however, the door panel is made of coated steel or painted. Due to the room conditions and wall constructions, the various constructions of door panels and doorframes are used. Each door is individually designed to ensure the durability and pleasant operation for many years.

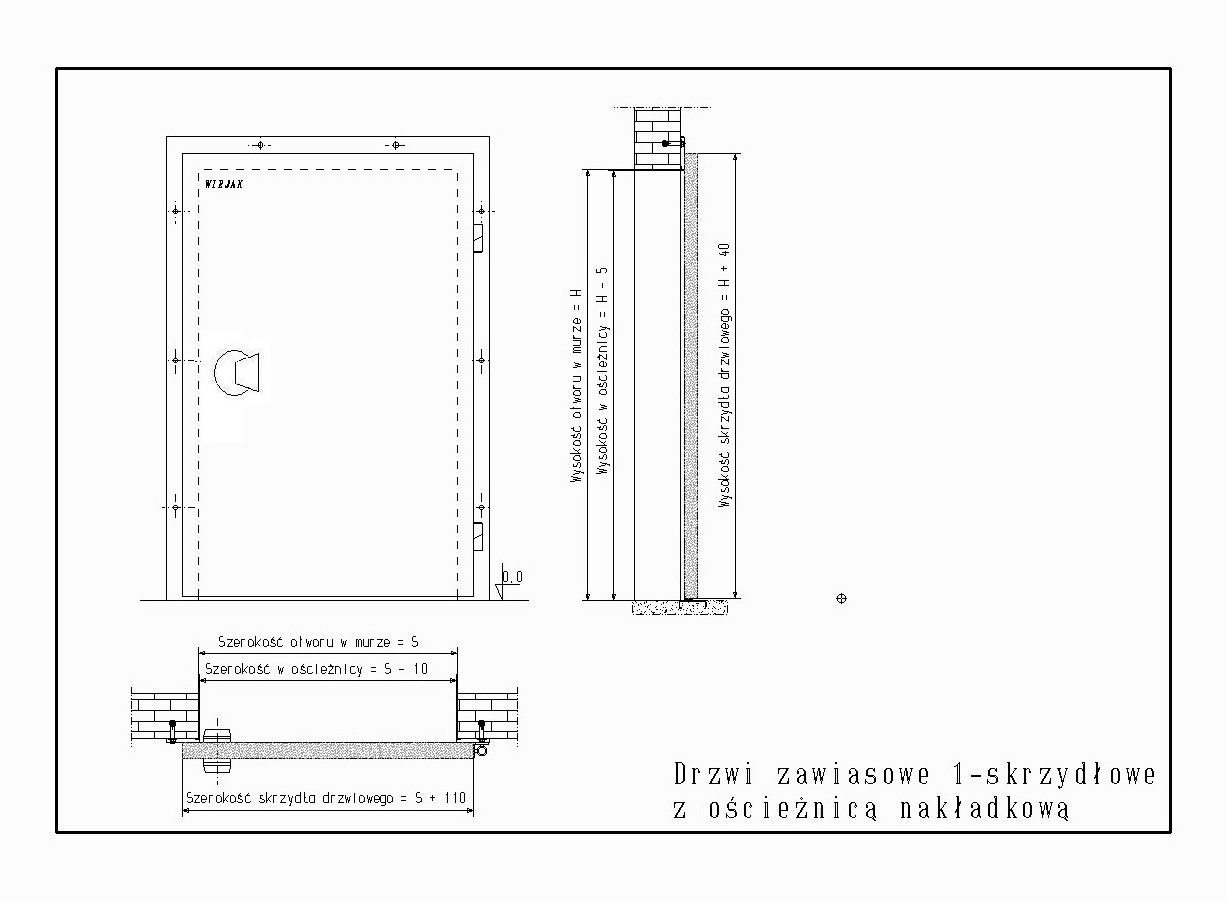

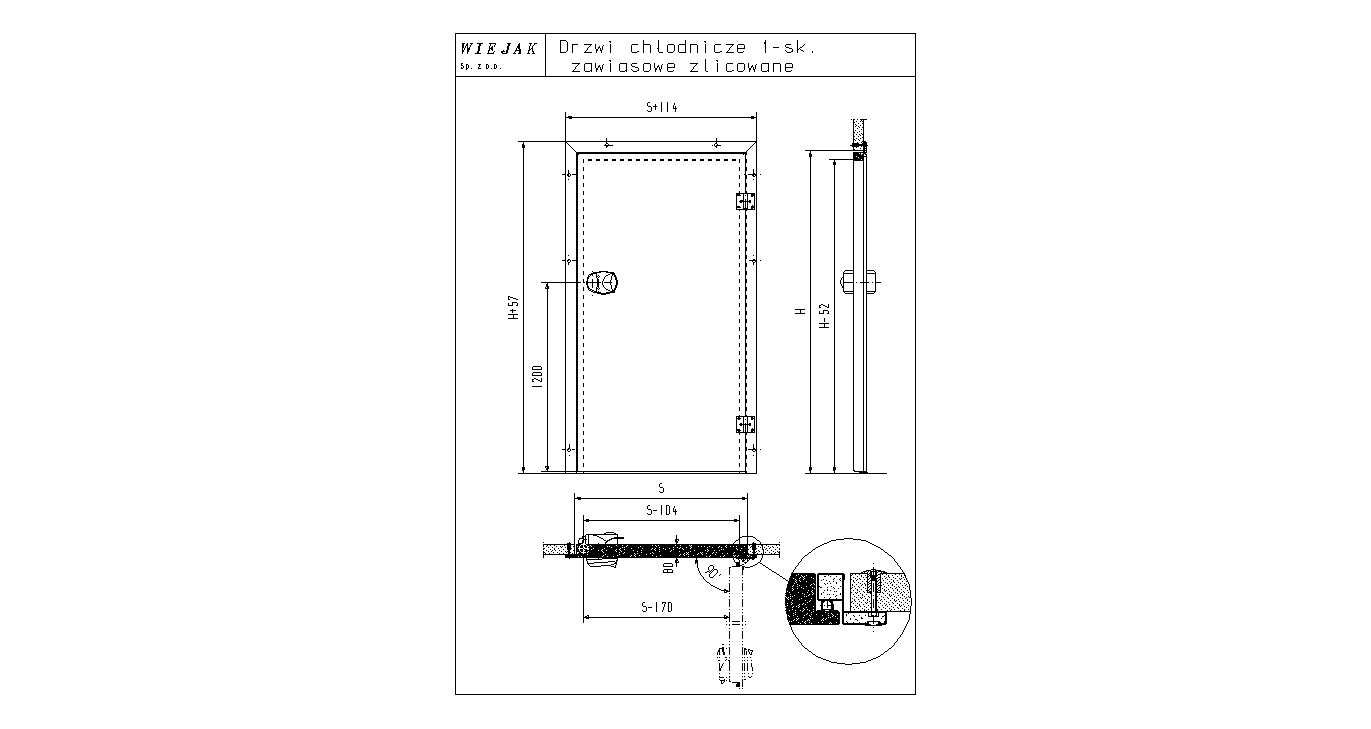

Hinged, single leaf doors

The chiller hinged doors can be produced in 3 constructional variants:

a) REBATED DOORS - standard solution

b) HALF-REBATED DOORS - door panel partially recessed in the doorframe

c) NON-REBATED DOORS - flush with the doorframe, used in narrow passages, corridors.

technical characteristics

gallery

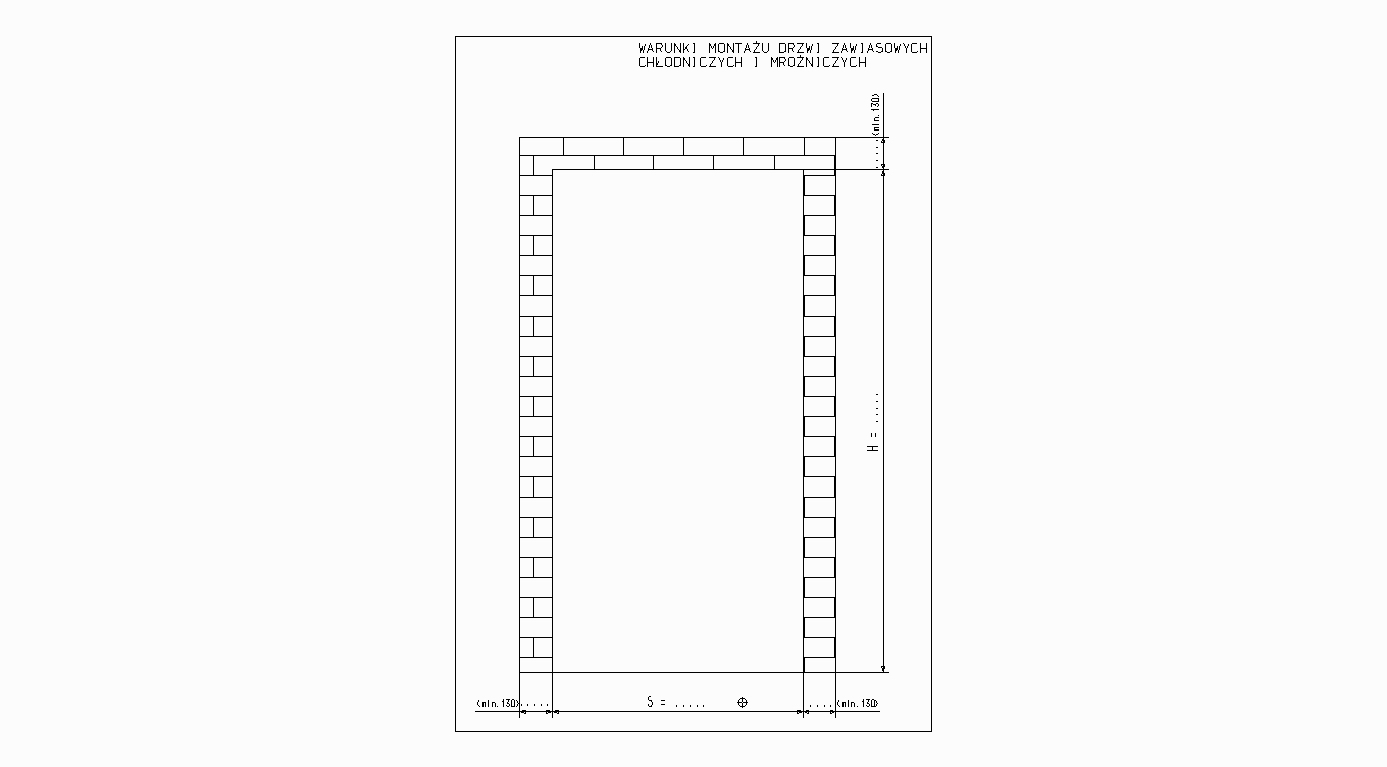

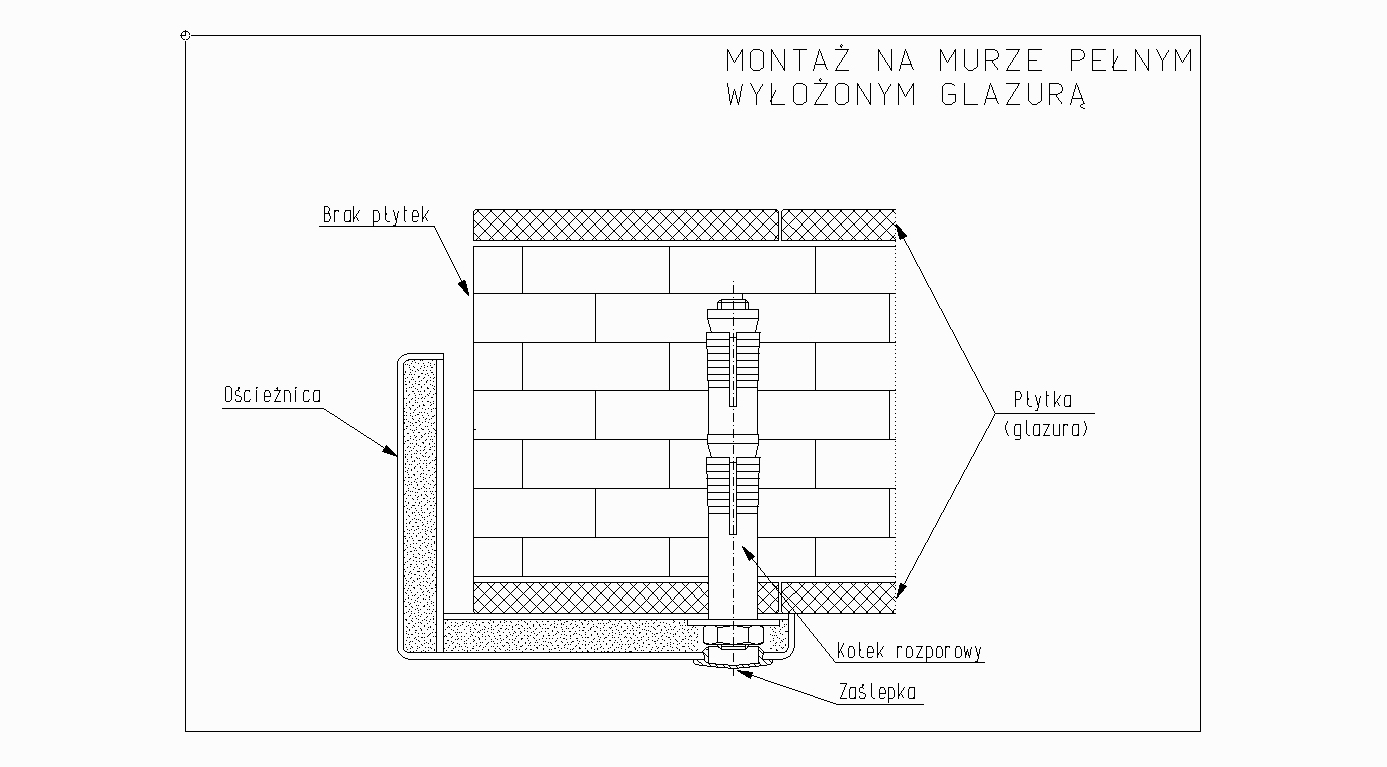

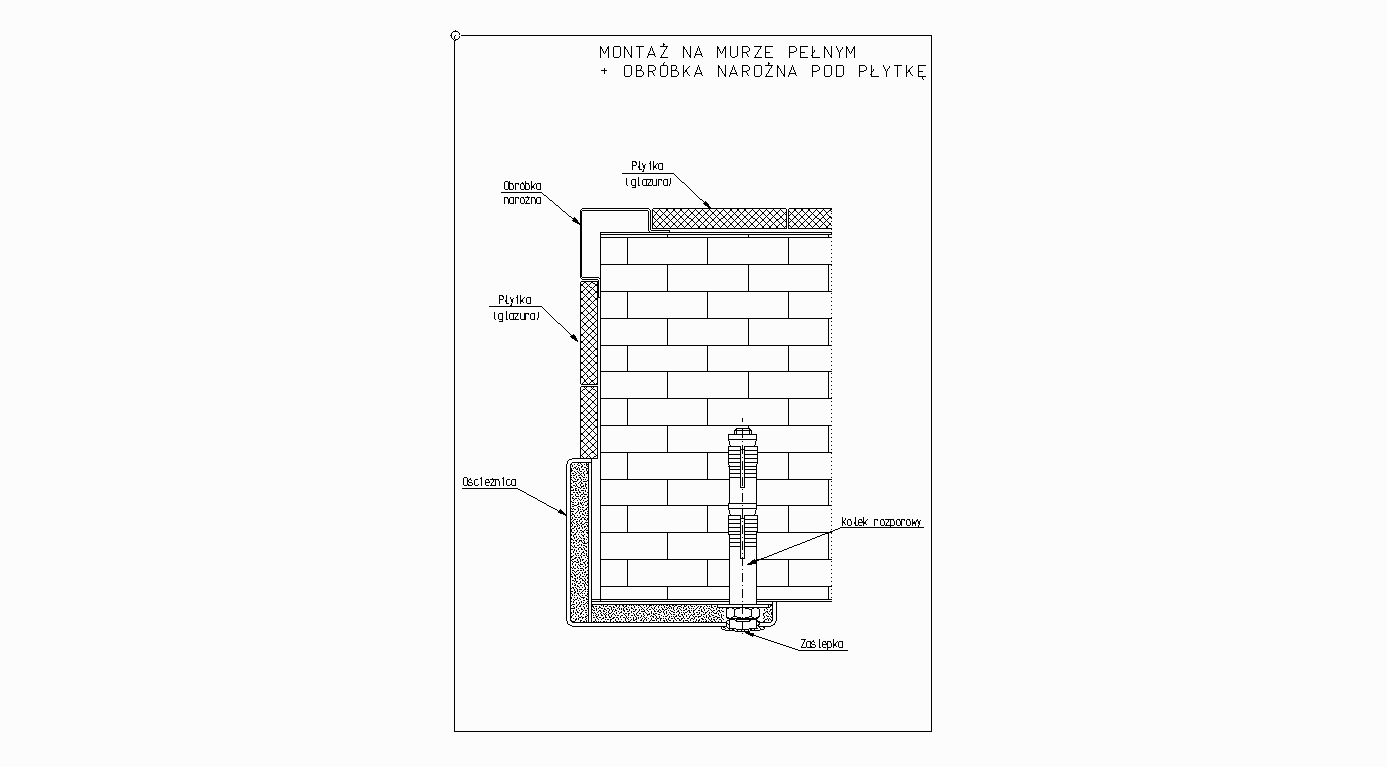

assembly

optional equipment

movies

frames

Rebated doors

The door panel fully covers the external side of the doorframe. This is standard and the most-cost effective solution, but requires the greatest amount of space on the side of the door installation.

technical characteristics

frames

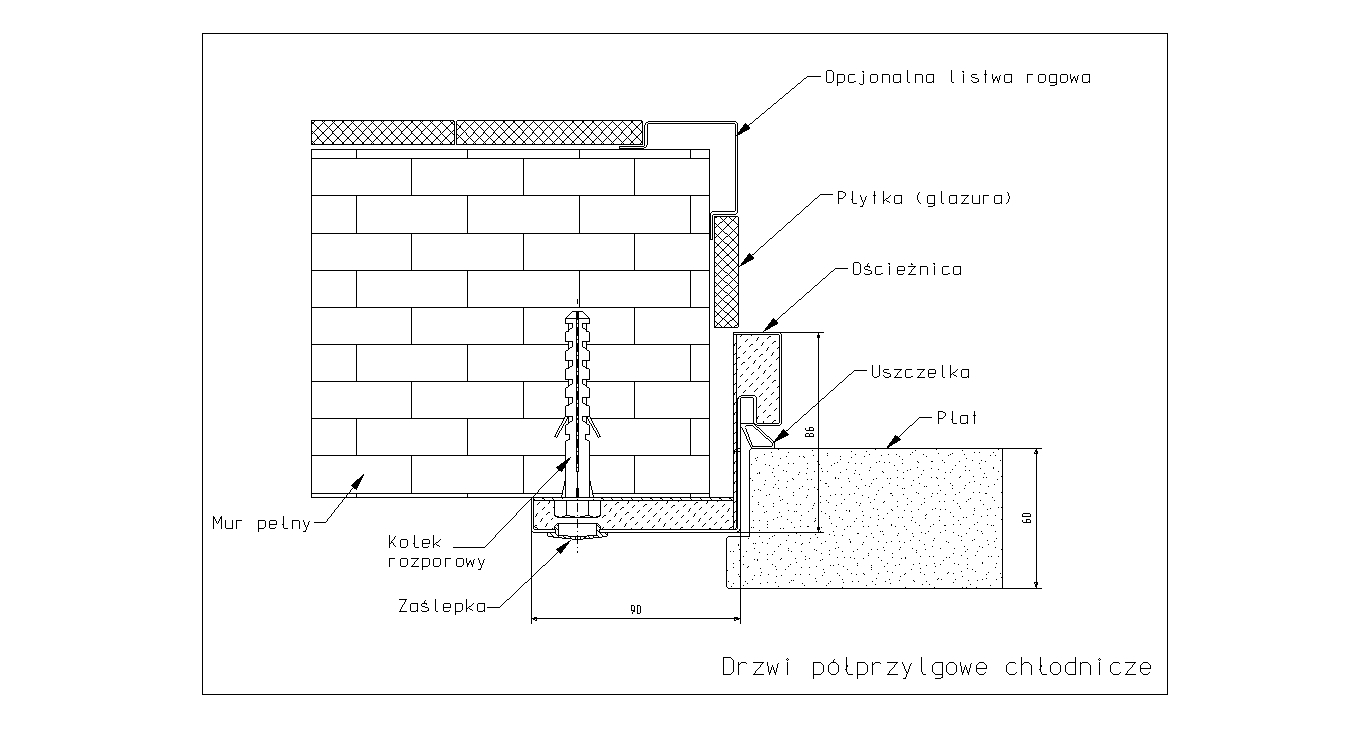

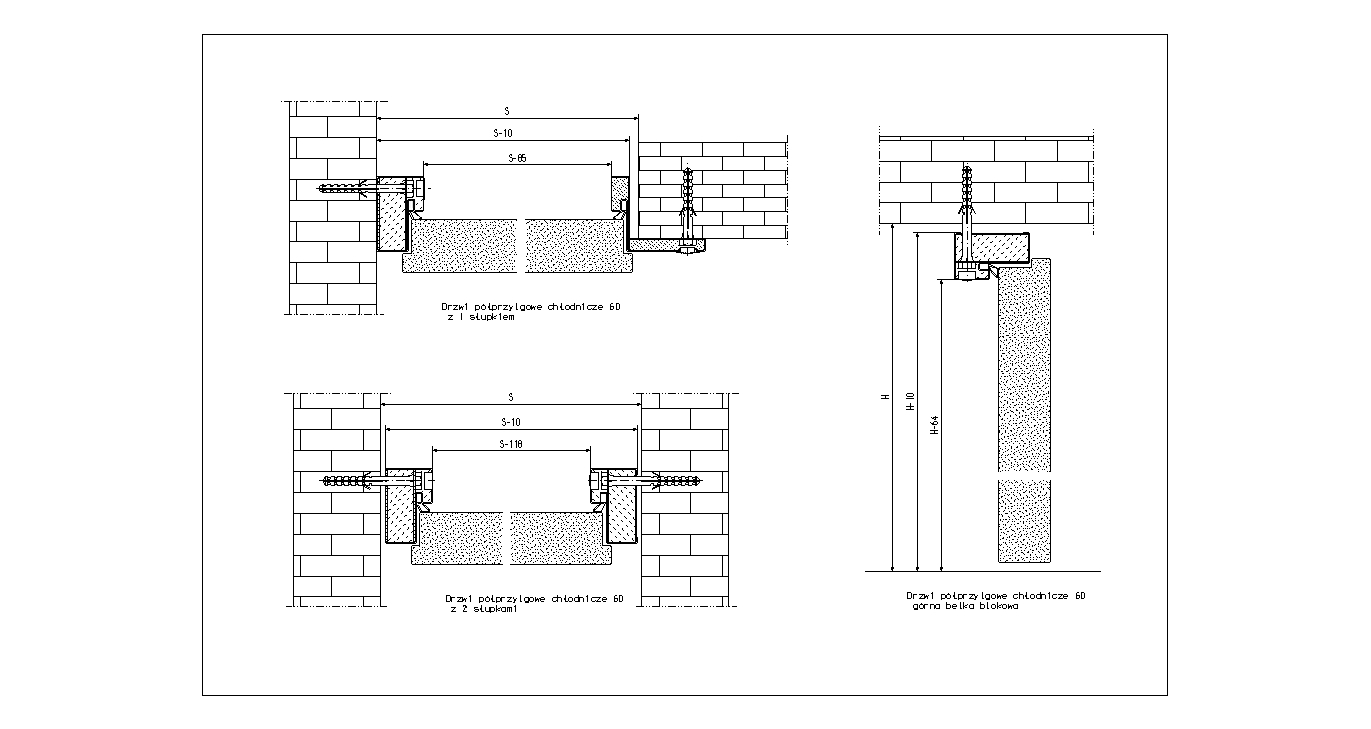

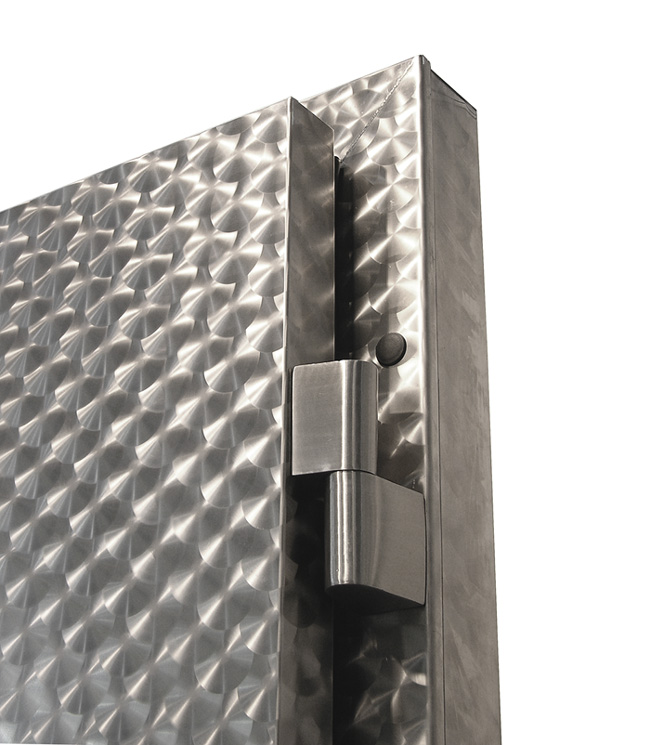

Half-rebated doors

The chiller half-rebated doors - door panel is partially recessed in the doorframe and partially covers the doorframe. The rigid and massive construction equipped with the hinges with visible bolts.

technical characteristics

frames

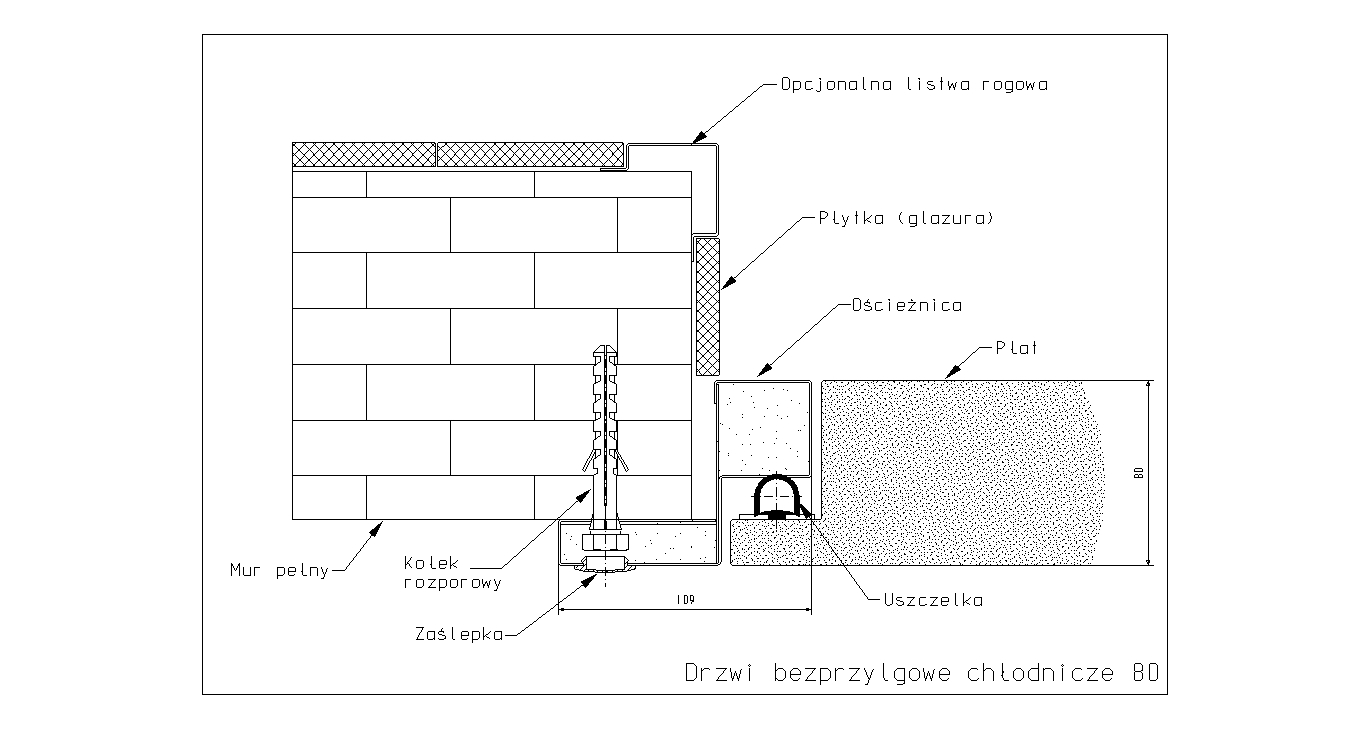

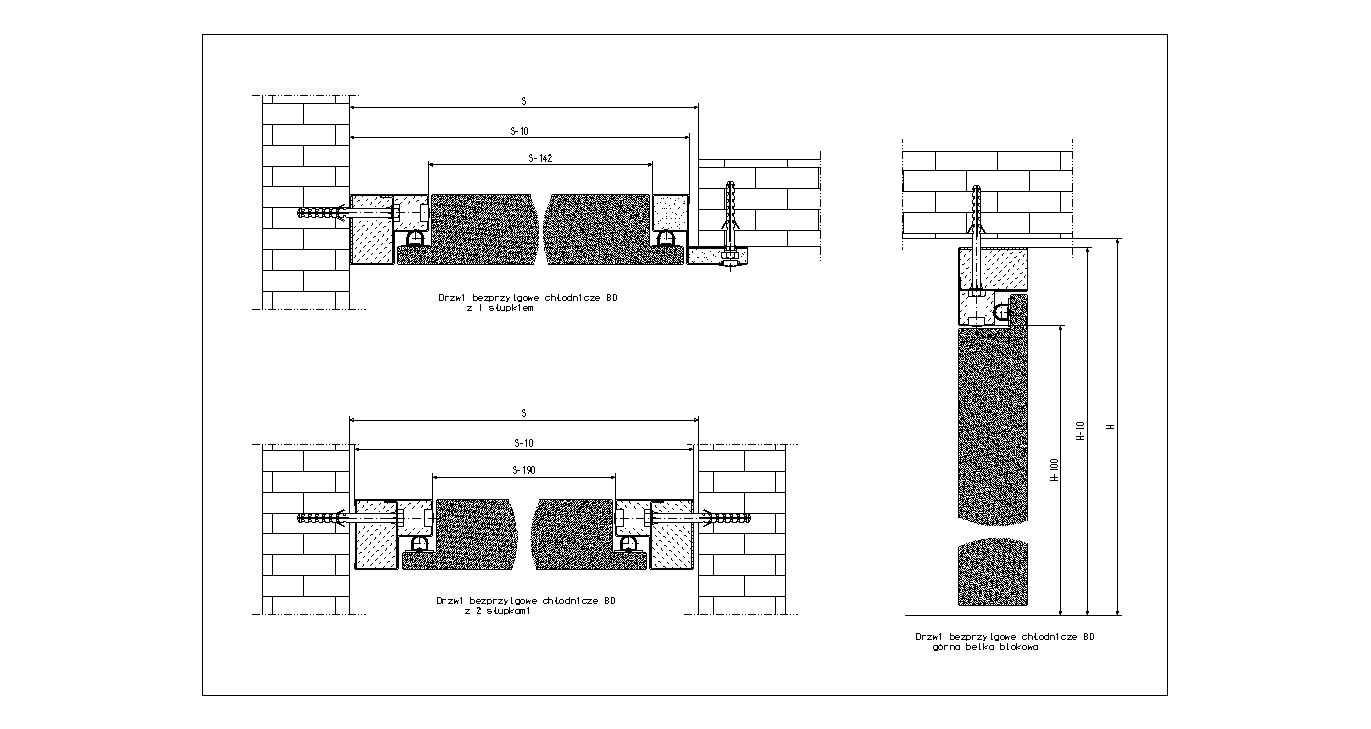

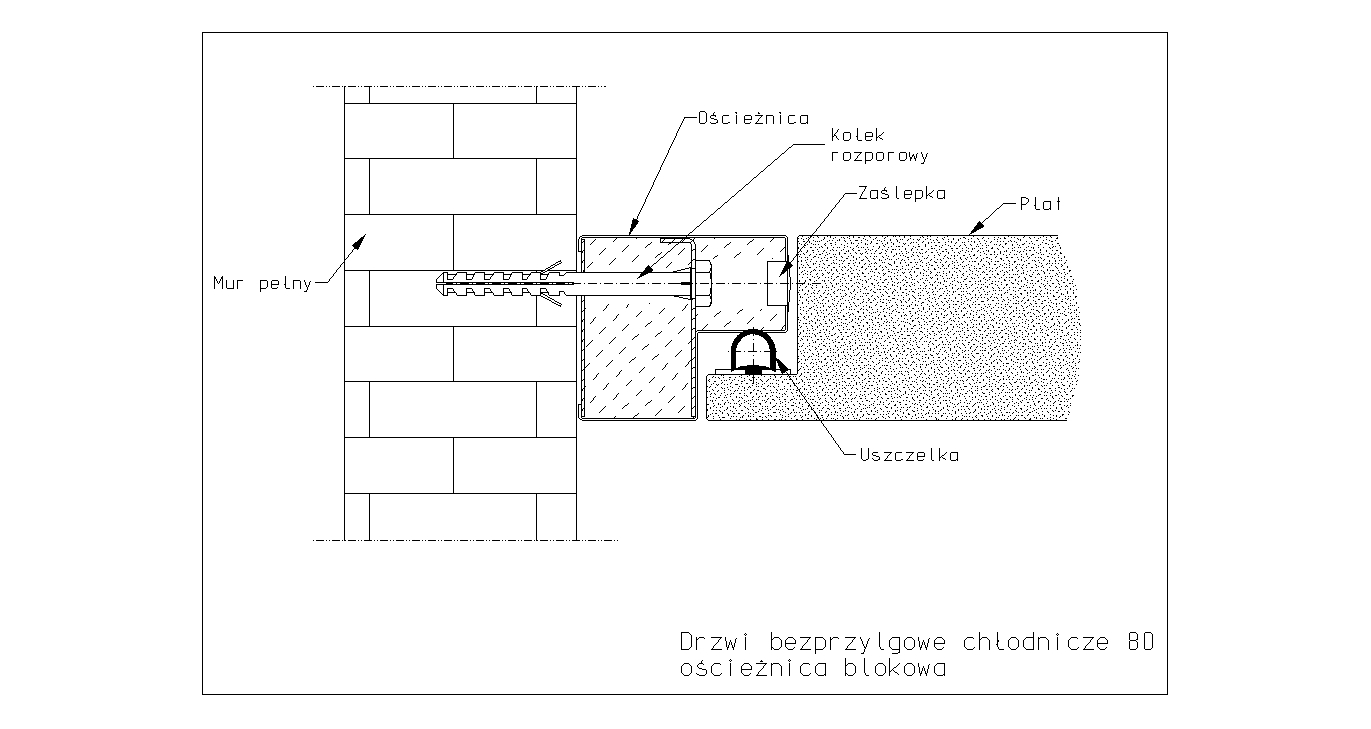

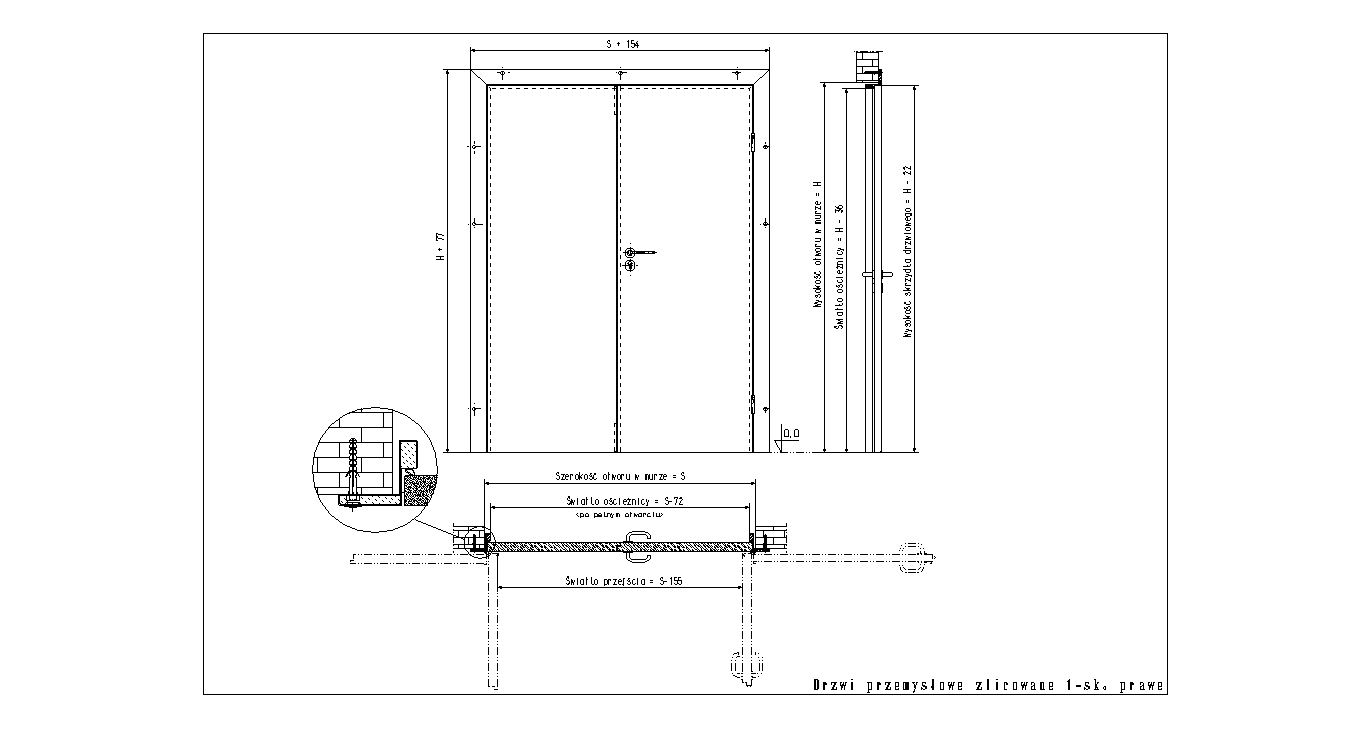

Non-rebated doors

The chiller non-rebated doors - door panel is fully recessed in the doorframe, forming a flush surface. This is a perfect solution in the corridors and passages where the doors cannot narrow the corridors.

technical characteristics

frames

Hinged, double leaf doors

The chiller hinged, double-leaf doors are used wherever the door niches must be quite broad and much more practical sliding doors cannot be used. These doors are equipped with the same seal as the sliding doors. The ergonomic lever-operated 3-point lock is used in the high double-leaf doors. The locking elements are hidden inside the doors, forming a smooth, easy-to-clean door coat.

The chiller hinged doors can be produced in 3 constructional variants:

a) REBATED DOORS - standard solution

b) HALF-REBATED DOORS - door panel partially recessed in the doorframe

c) NON-REBATED DOORS - flush with the doorframe, used in narrow passages, corridors.

technical characteristics

gallery

assembly

optional equipment

movies

frames

Rebated doors

The door panel fully covers the external side of the doorframe. This is standard and the most-cost effective solution, but requires the greatest amount of space on the side of the door installation.

technical characteristics

frames

Half-rebated doors

The chiller half-rebated doors - door panel is partially recessed in the doorframe and partially covers the doorframe. The rigid and massive construction equipped with the hinges with visible bolts.

technical characteristics

frames

Non-rebated doors

The chiller non-rebated doors - door panel is fully recessed in the doorframe, forming a flush surface. This is a perfect solution in the corridors and passages where the doors cannot narrow the corridors.

technical characteristics

frames

Sliding, single leaf doors

Specialists say:

“The floors and doors are two of the most exploited elements in the industrial plants. Their execution should be entrusted to the specialists with the extensive knowledge and experience”.

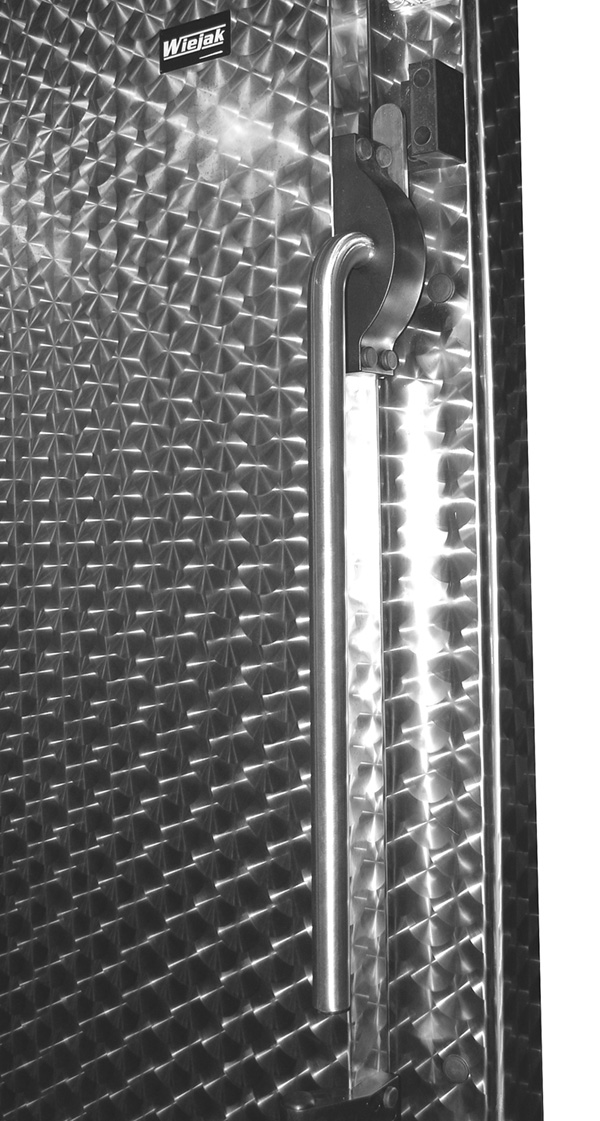

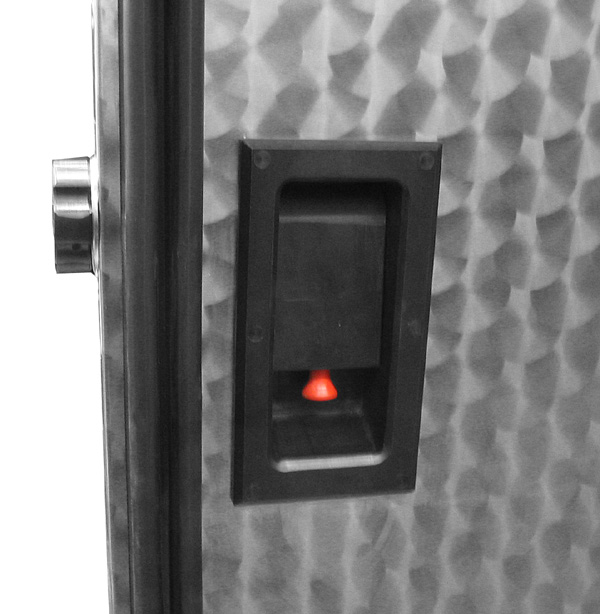

Our sliding doors are prepared to operate in the toughest conditions. They effectively work for thousands of our customers each year, earn their trust and good reputation.

technical characteristics

gallery

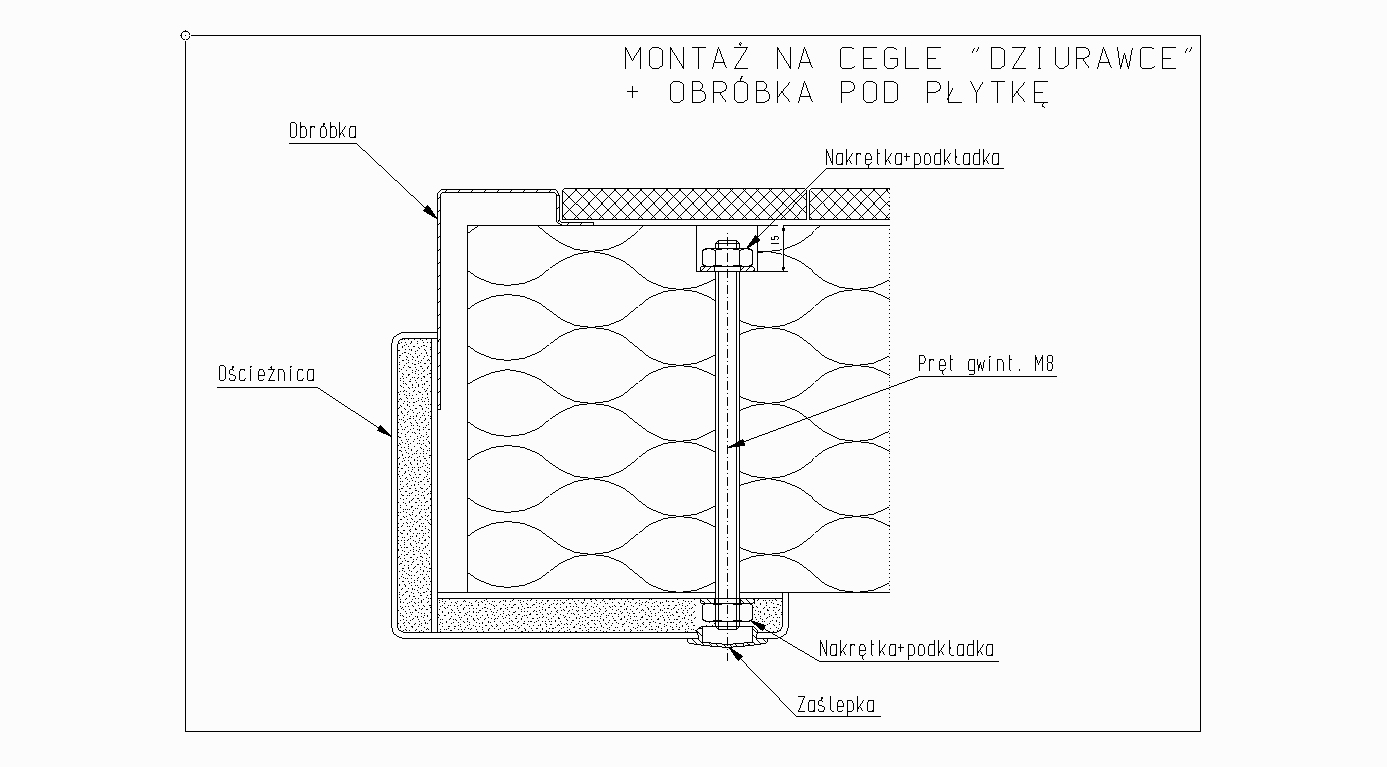

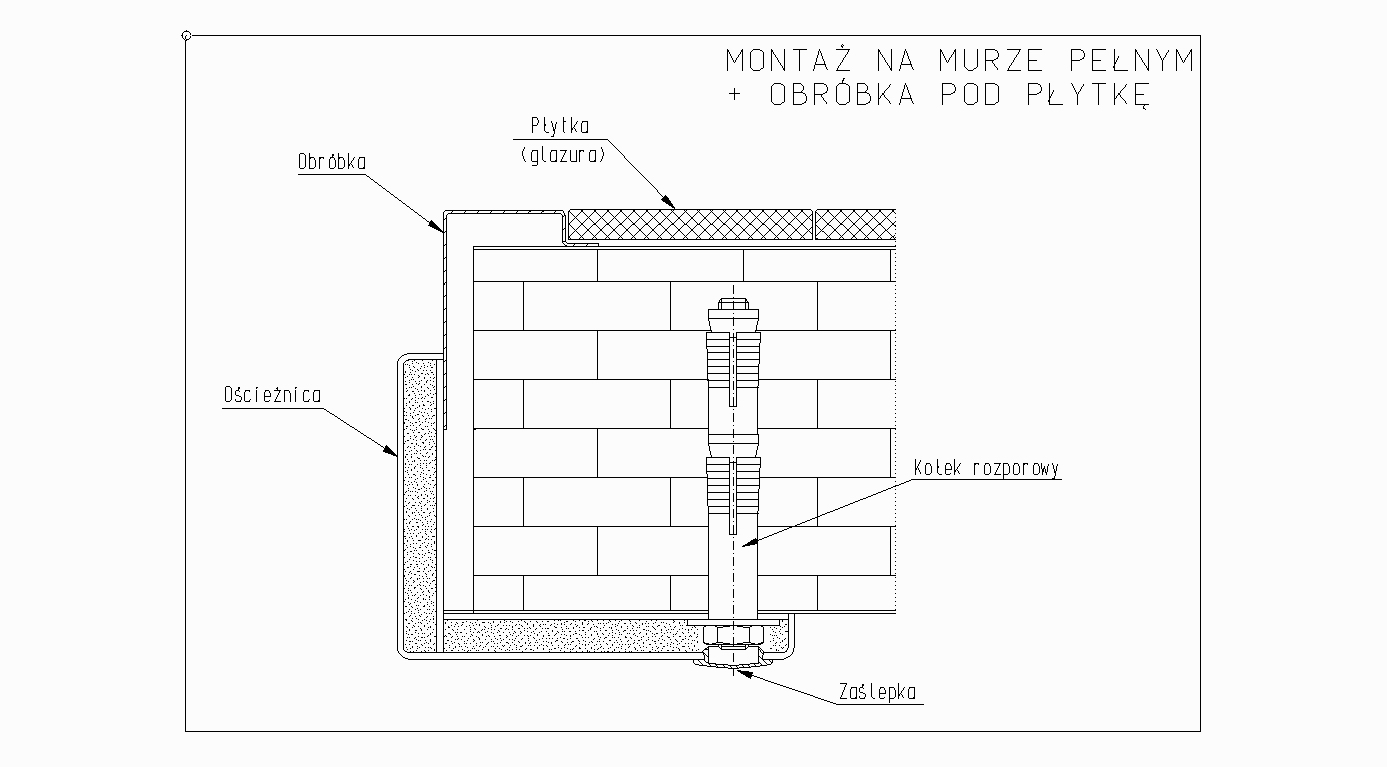

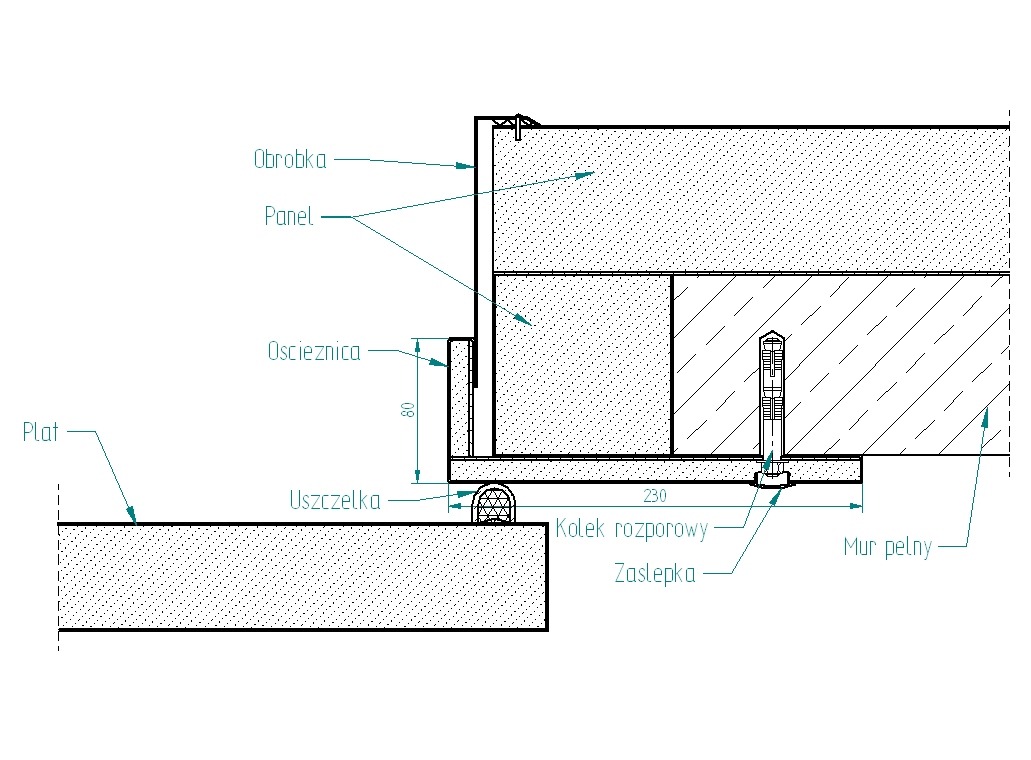

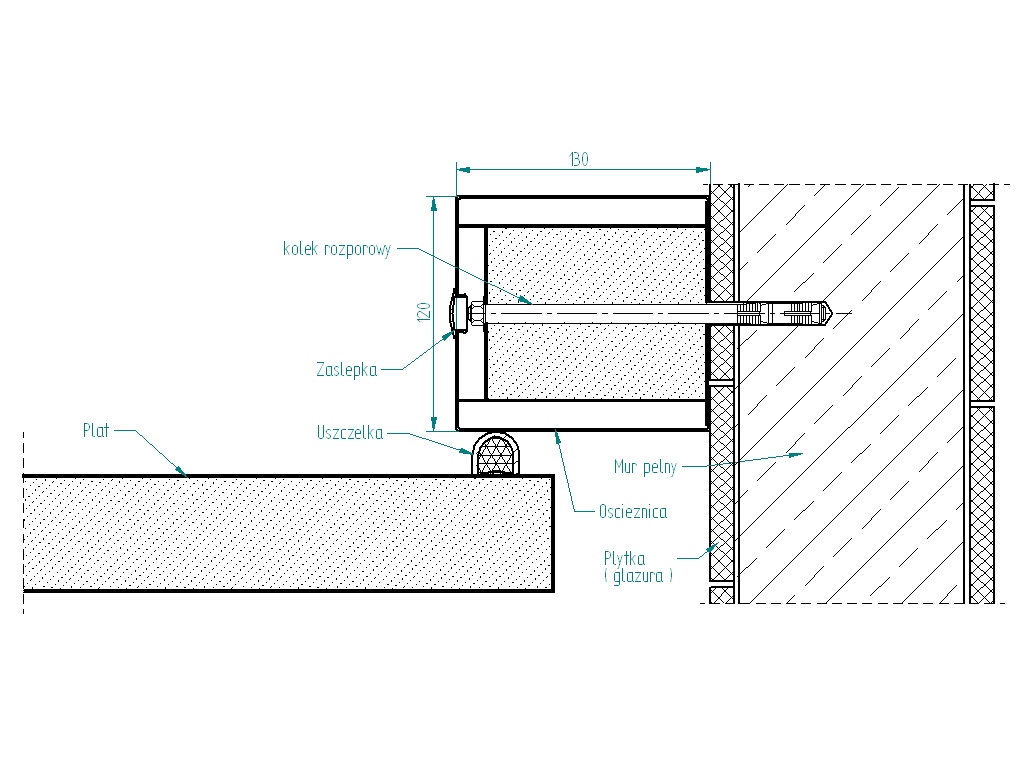

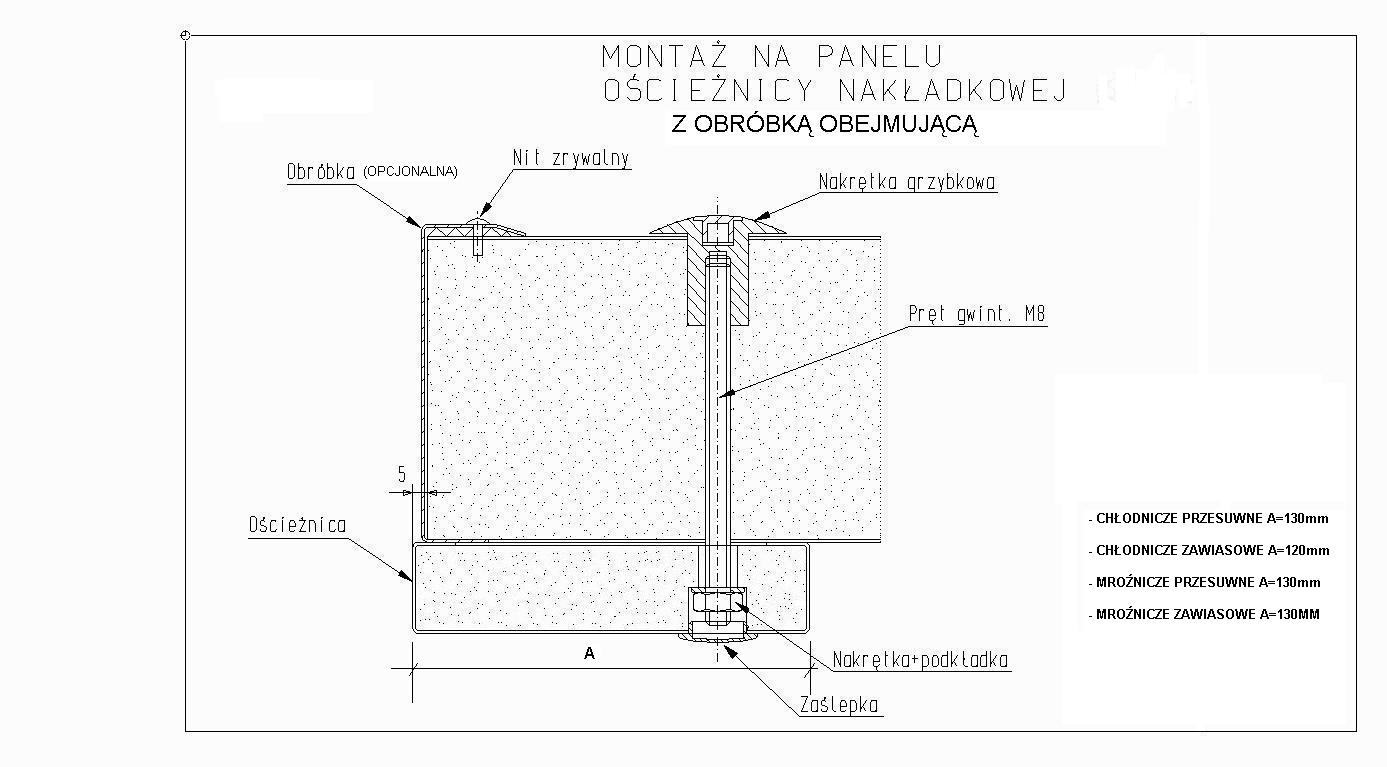

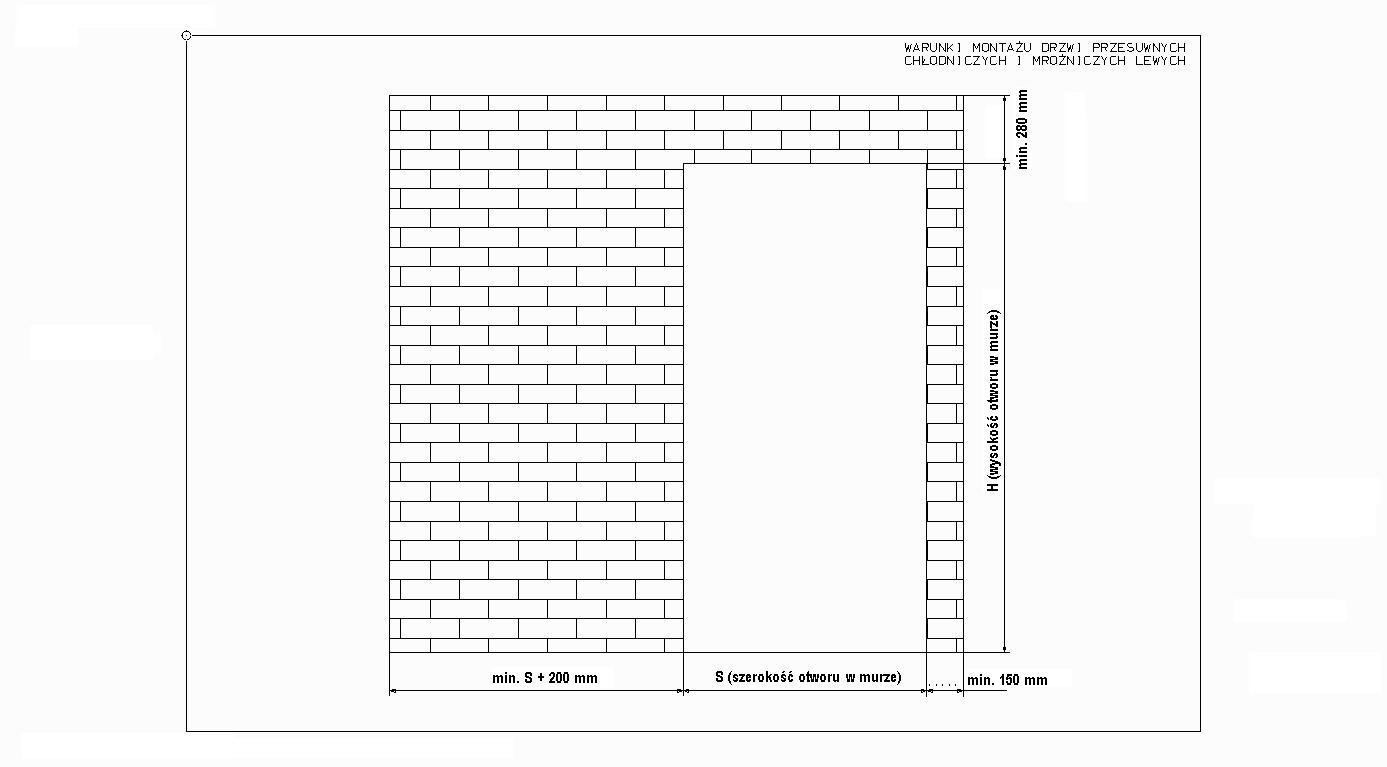

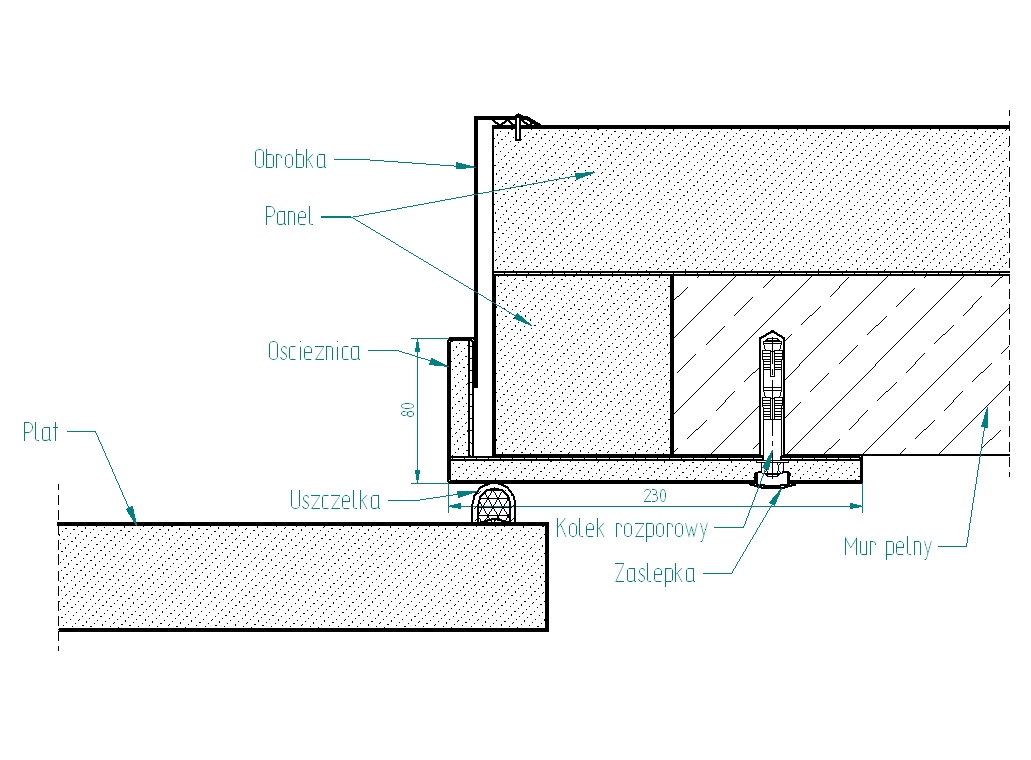

assembly

optional equipment

movies

frames

Classical sliding system

The classical sliding system is a standard rail. The construction, refined over time, is made entirely of stainless steel. The system cover of the door with the classical sliding rail is made of the same material as the door panel. The polyethylene rollers are specially designed to provide a quiet operation and the durability of the door.

technical characteristics

Pipe rail system

The pipe rail system consists of aesthetically brushed stainless steel pipe and two large, specifically profiled guide rollers. Due to the special profile of the rollers and the pipe, just as in the classical system, the door falls down and pushes to the doorframe, while closing.

technical characteristics

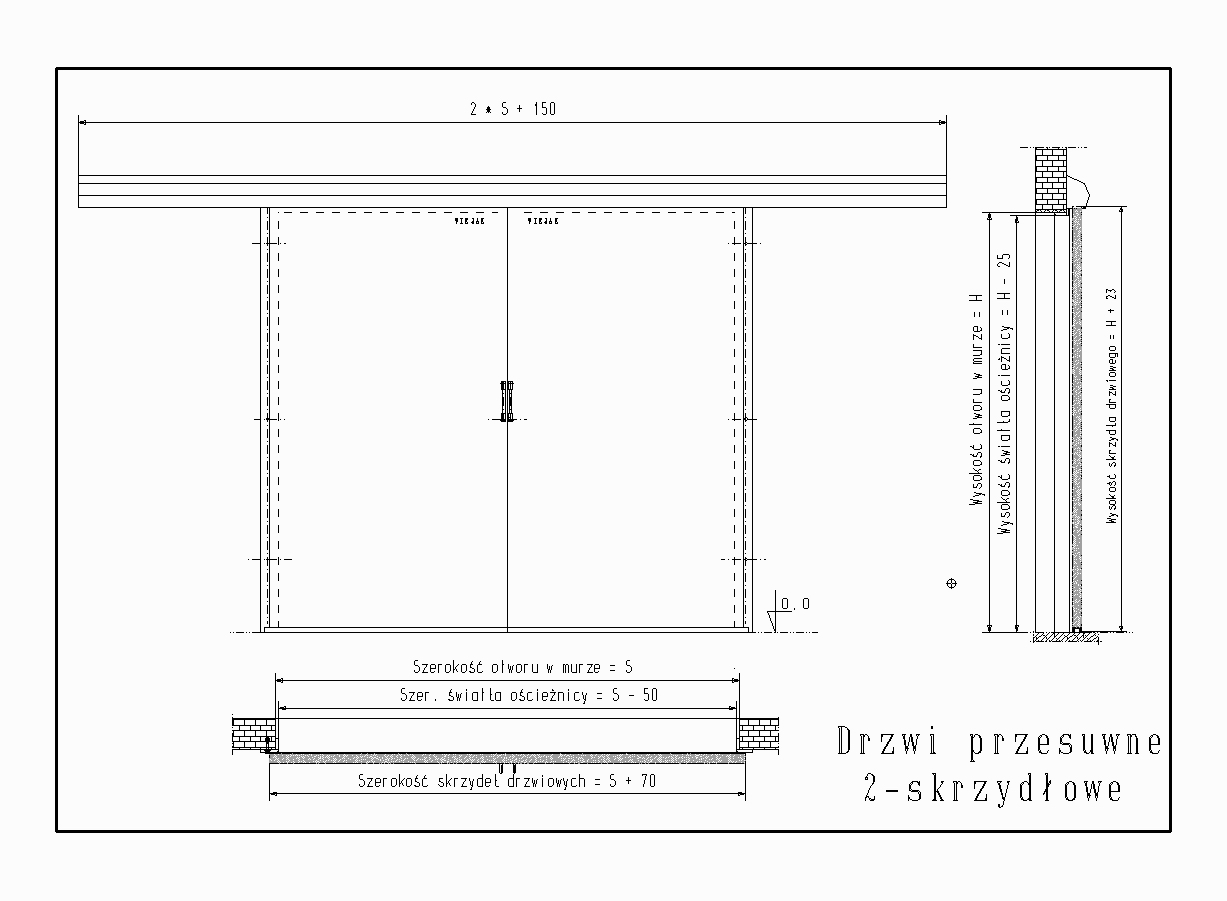

Sliding, double leaf doors

Specialists say:

“The floors and doors are two of the most exploited elements in the industrial plants. Their execution should be entrusted to the specialists with the extensive knowledge and experience”.

Our sliding doors are prepared to operate in the toughest conditions. They effectively work for thousands of our customers each year, earn their trust and good reputation.

technical characteristics

gallery

assembly

optional equipment

movies

frames

Classical sliding system

The classical sliding system is a standard rail. The construction, refined over time, is made entirely of stainless steel. The system cover of the door with the classical sliding rail is made of the same material as the door panel. The polyethylene rollers are specially designed to provide a quiet operation and the durability of the door.

technical characteristics

Pipe rail system

The pipe rail system consists of aesthetically brushed stainless steel pipe and two large, specifically profiled guide rollers. Due to the special profile of the rollers and the pipe, just as in the classical system, the door falls down and pushes to the doorframe, while closing.

technical characteristics

.jpg)