Industrial doors

Not only freezer rooms and chiller rooms require solid doors in the industry plants. Other rooms should also be equipped with specifically designed doors, quite different from the standard solutions available on the market. The designs of our industrial doors are based on the long-term experience, both from the point of view of the door user and the door producer. All, even the smallest industrial doors, are separately designed for the specific door niche. We offer almost countless number of dedicated solutions for doorframes, door panels and optional equipment.

Hinged, single leaf doors

Door panel: They can be made of stainless steel, coated steel or painted according to RAL palette. The door panels can be constructed as rebated panels or as non-rebated panels. They are always filled with highly compressed polyurethane foam that provides exceptional rigidity and lightness. All the reinforcements inside the door panels are made of stainless steel. The thickness is 40 mm.

Sealing: Pressed black EPDM rubber seal. Optional white silicone seal.

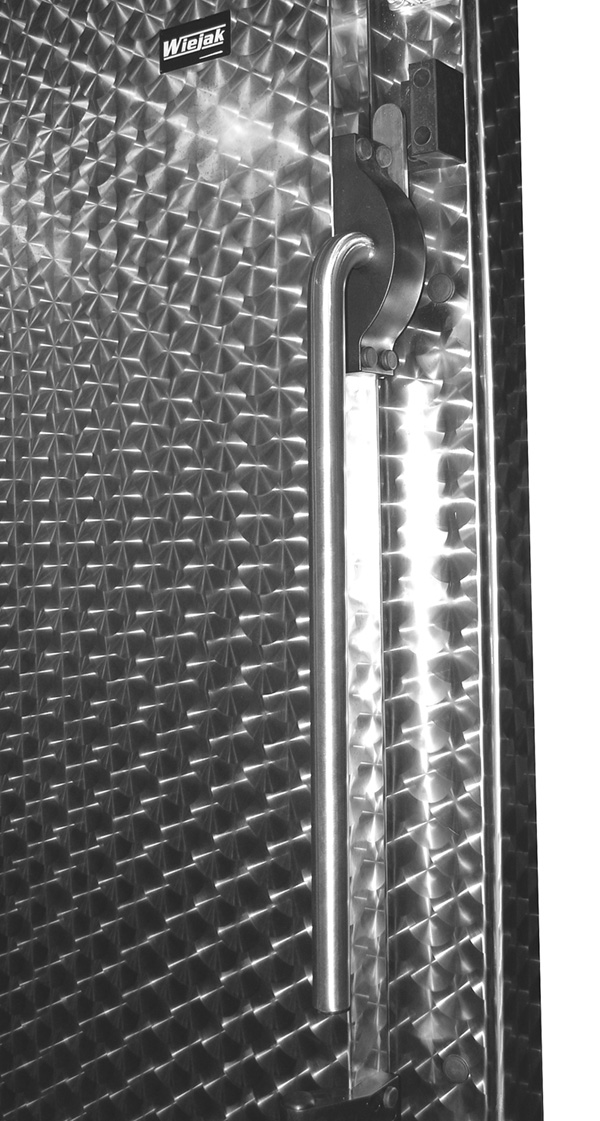

Hinges: Depending on the weight of the door leaf, we use two or three stainless steel hinges (steel grade 304). They can be produced in straight or oblique (up-down or tightening) versions. The mounting holes of the hinges in the non-rebated doors are not visible.

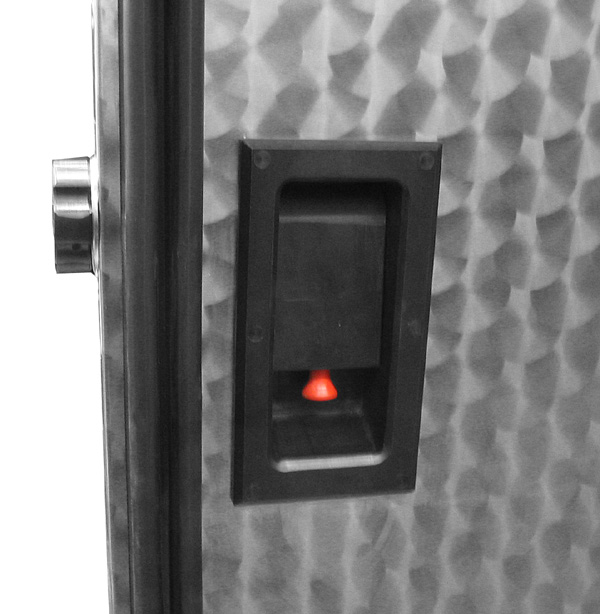

Latches: Stainless steel door handle with round rosettes and key-lock, as a standard. Optionally, other types of door handles, anti-panic locks, roller locks, electric lock and other solutions tailored to the user’s needs.

gallery

optional equipment

movies

frames

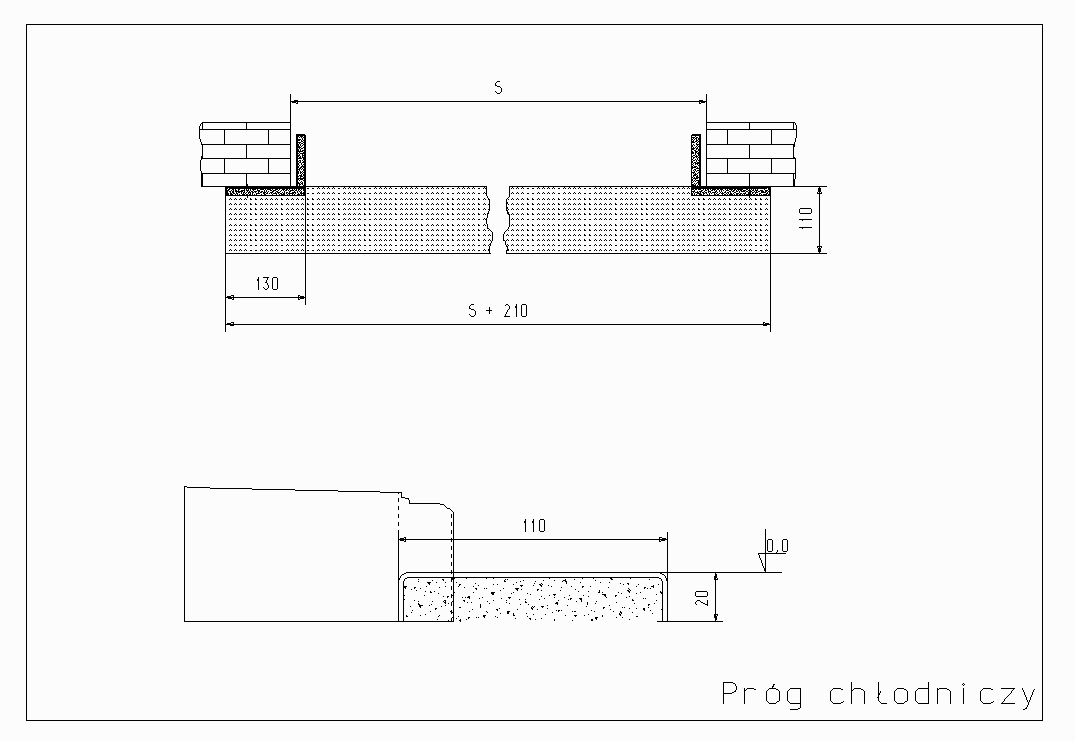

Rebated doors

The rebated door - door panel is partially recessed in the doorframe and partially covers the doorframe. The rebated door requires only 66 mm of the allowance in the door niche in order to obtain the specific clearance of the door. When the door is opened at an angle of 90°, the door panel does not go into the door clearance. They are always filled with highly compressed polyurethane foam that provides exceptional rigidity and lightness. All the reinforcements inside the door panels are made of stainless steel. The thickness is 40 mm.

technical characteristics

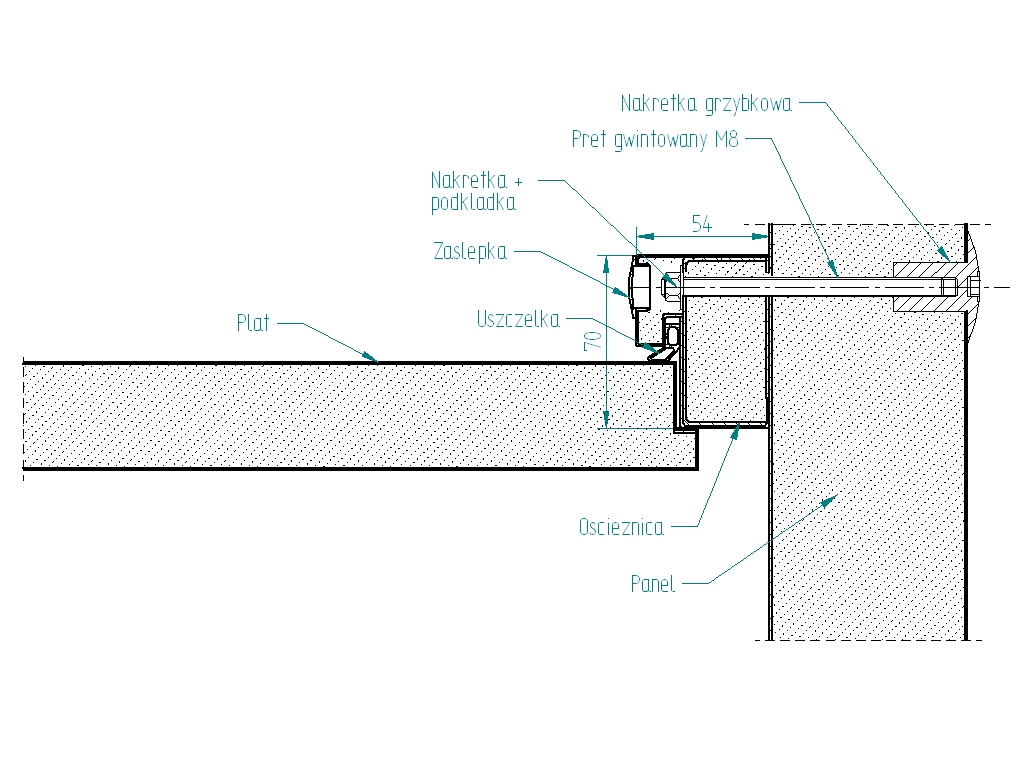

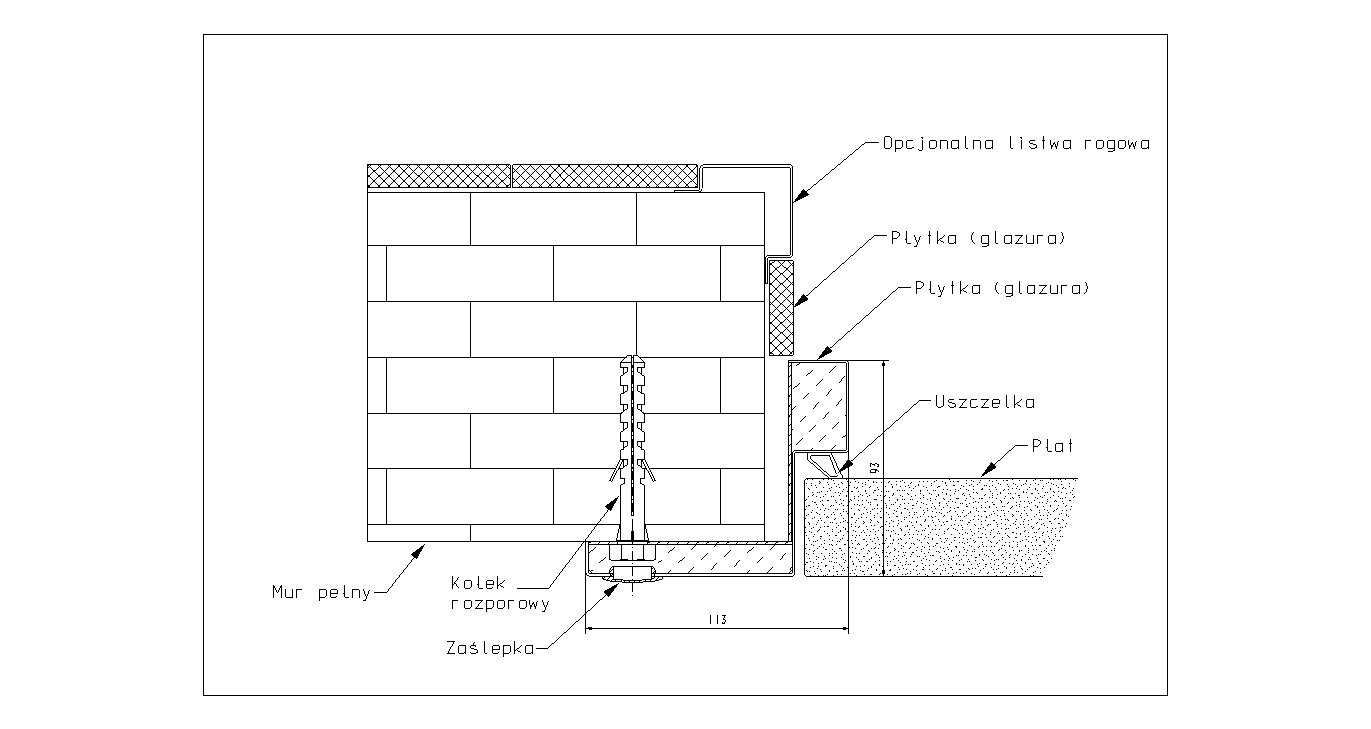

assembly

frames

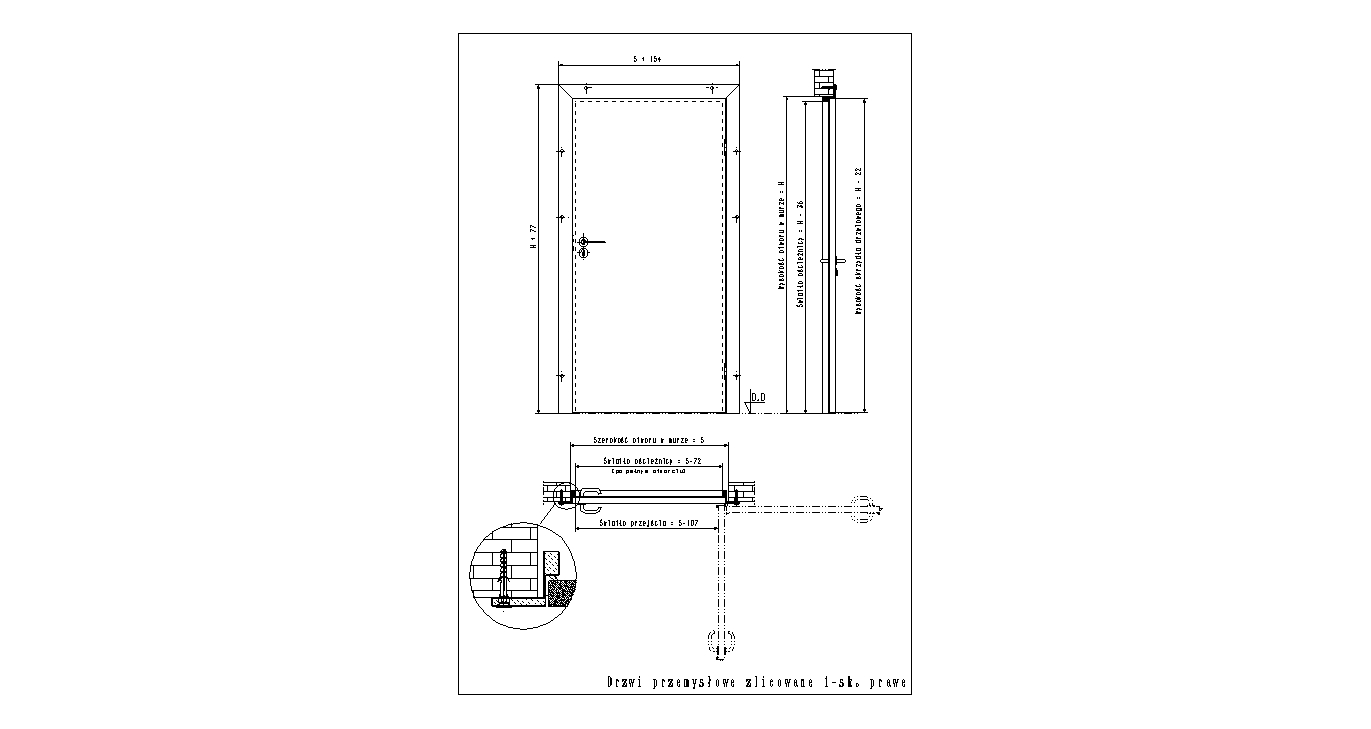

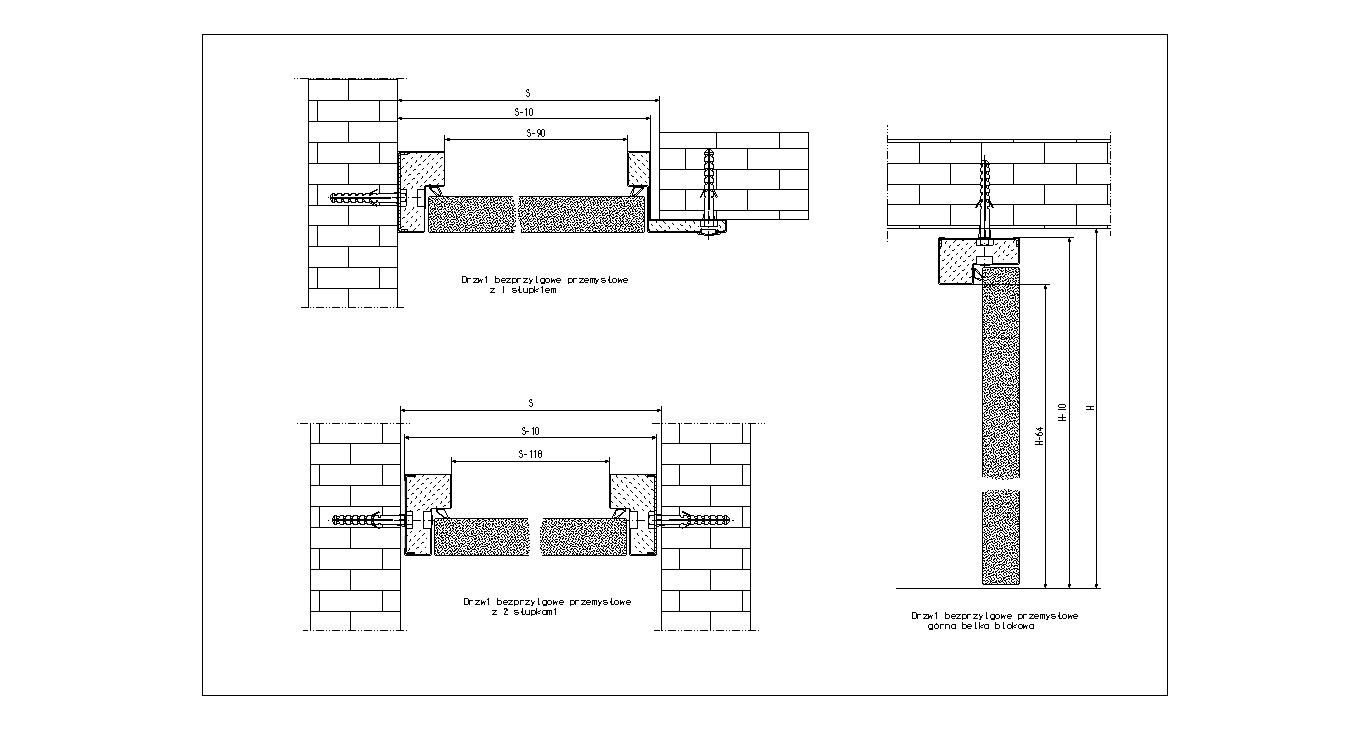

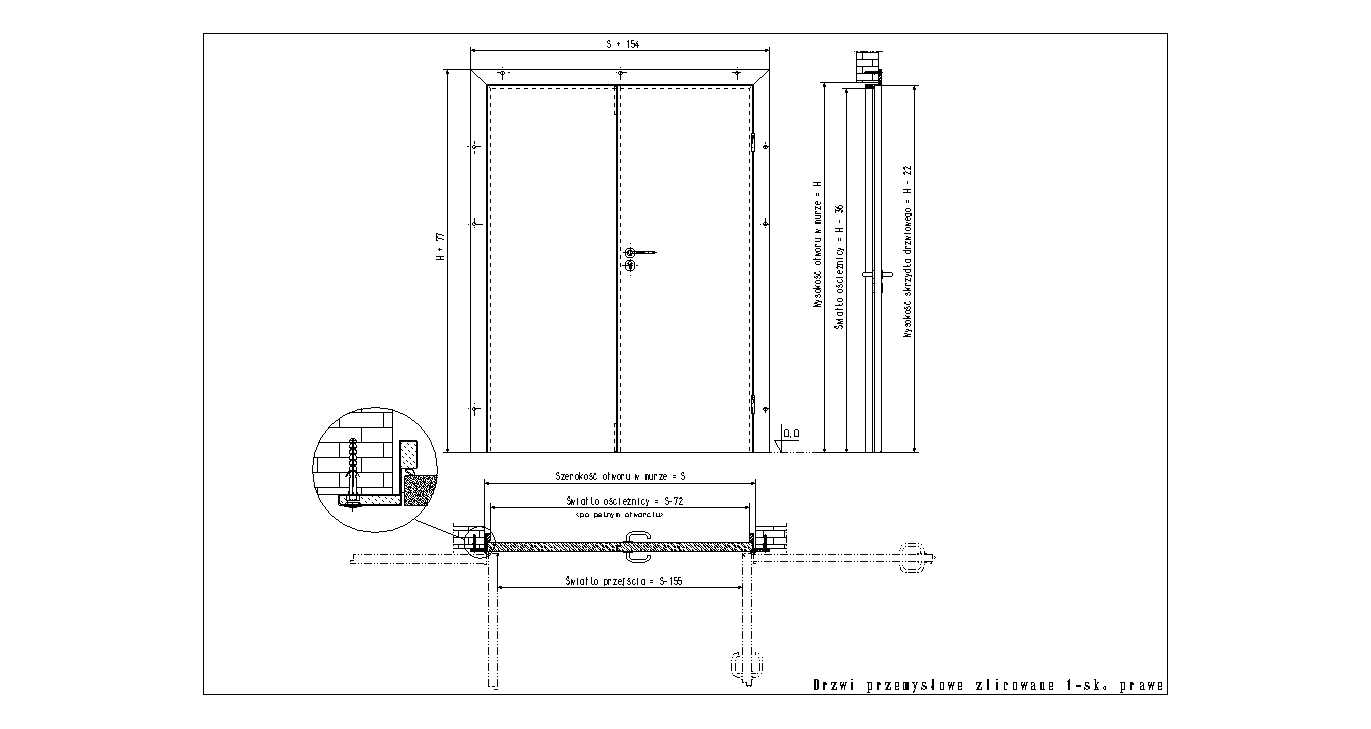

Non-rebated doors

The door panel is completely hidden in the doorframe, forming a uniform plane. When the door is opened at an angle of 90°, the door panel goes into the door clearance, therefore, more mounting space should be foreseen in order to obtain the specific passage clearance than in case of the rebated door.

technical characteristics

frames

Hinged, double leaf doors

The industrial hinged double-leaf doors are the equivalent of the single-leaf doors, but this type of the doors is used in the wider door niches. Just as the single-leaf doors, these doors are also equipped with the locks. The handles and doorplates are made of aesthetically ground stainless steel.

Door panel: They can be made of stainless steel, coated steel or painted according to RAL palette. The door panels can be constructed as rebated panels or as non-rebated panels. They are always filled with highly compressed polyurethane foam that provides exceptional rigidity and lightness. All the reinforcements inside the door panels are made of stainless steel. The thickness is 50 mm.

Sealing: Pressed black EPDM rubber seal. Optional white silicone seal.

Hinges: Depending on the weight of the door leaf, we use two or three stainless steel hinges (steel grade 304). They can be produced in a straight or oblique (up-down or tightening) version. The mounting holes of the hinges in the non-rebated doors are not visible.

Latches: Stainless steel door handle with round rosettes and key-lock, as a standard. Optionally, other types of door handles, anti-panic locks, roller locks, electric lock and other solutions tailored to the user’s needs.

gallery

optional equipment

movies

frames

Rebated doors

The rebated door - door panel is partially recessed in the doorframe and partially covers the doorframe. The rigid and massive construction equipped with the hinges with visible bolts. The rebated door requires only 66 mm of the allowance in the door niche in order to obtain the specific clearance of the door. When the door is opened at an angle of 90°, the door panel does not go into the door clearance.

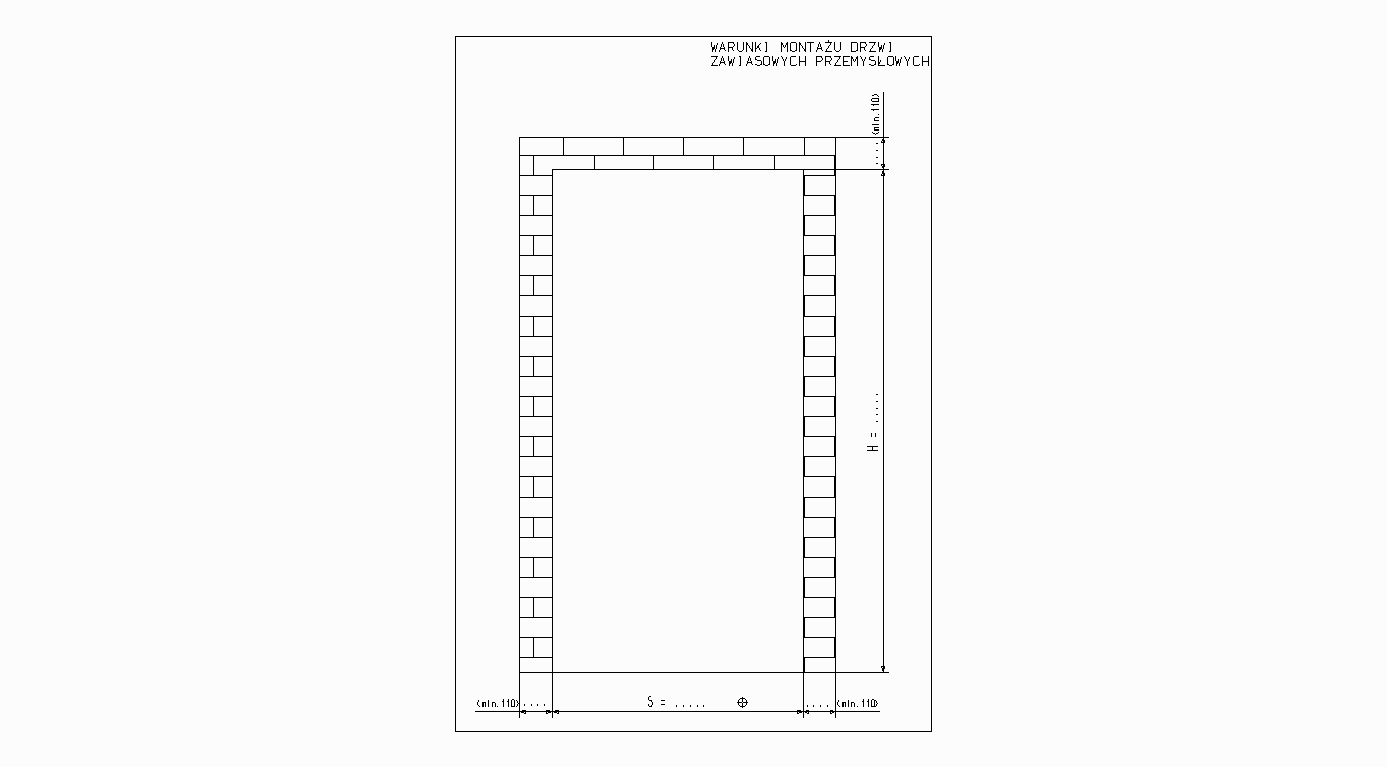

technical characteristics

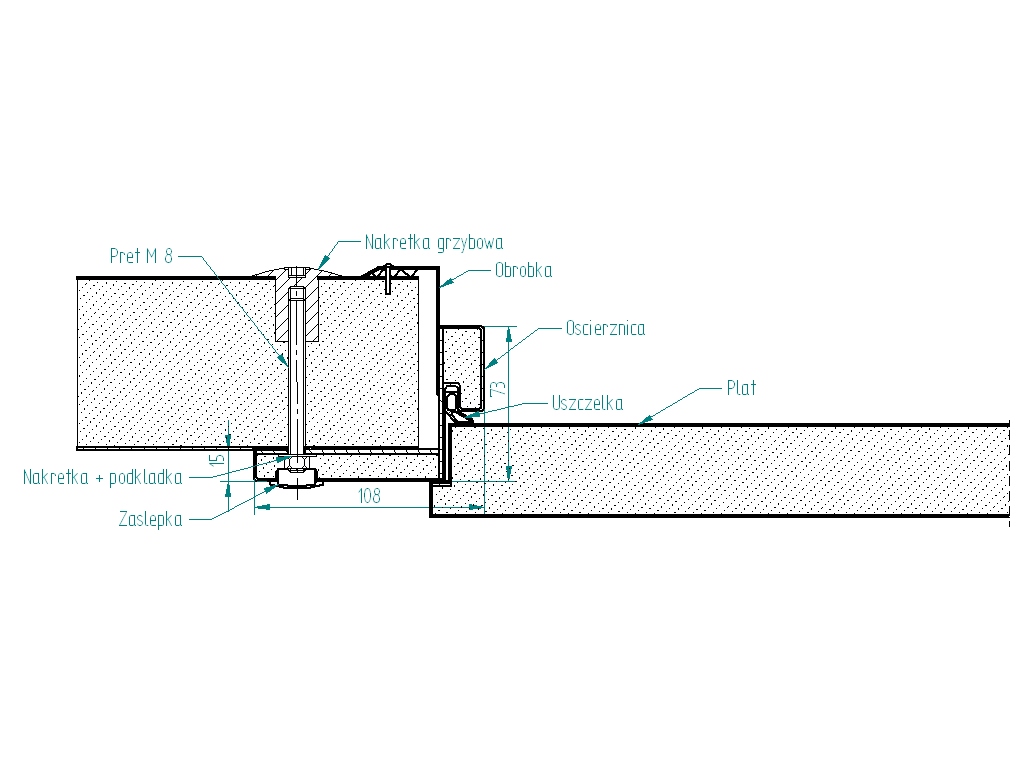

assembly

frames

Non-rebated doors

The door panel is completely hidden in the doorframe, forming a uniform plane. When the door is opened at an angle of 90°, the door panel goes into the door clearance, therefore, more mounting space should be foreseen in order to obtain the specific passage clearance than in case of the rebated doors.

technical characteristics

frames

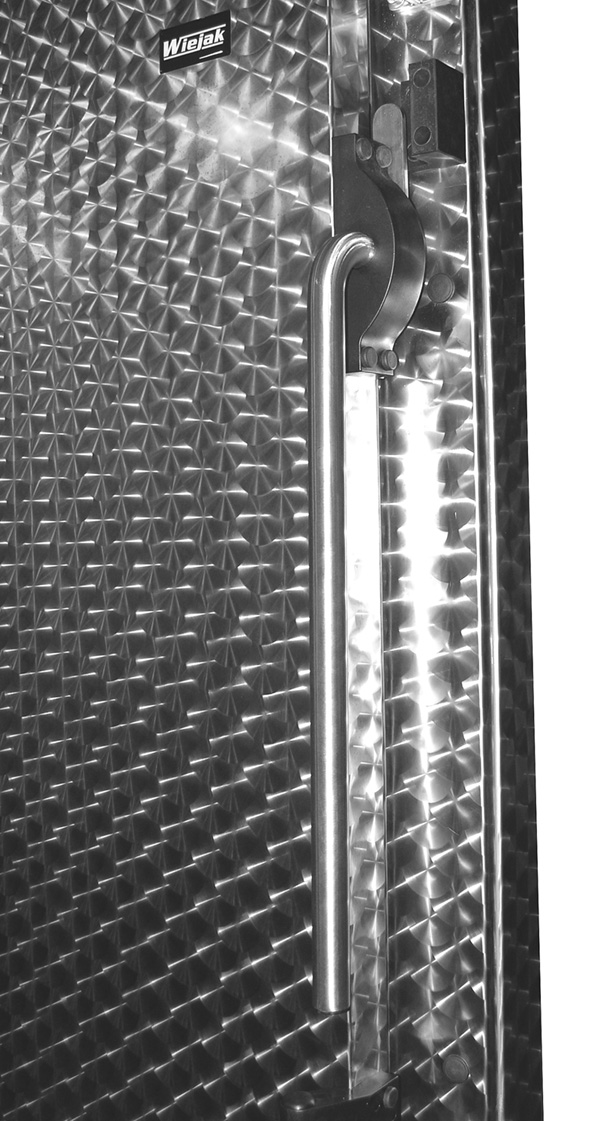

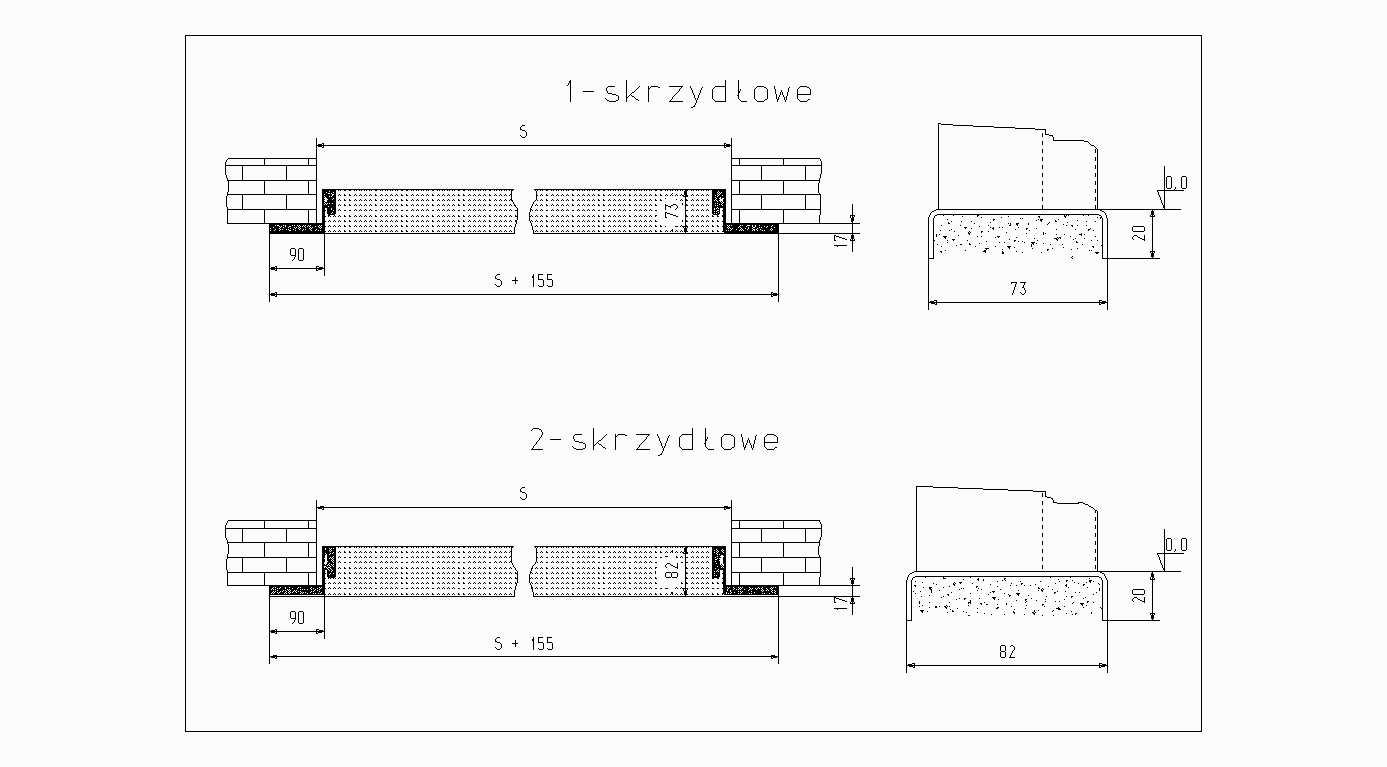

Sliding, single leaf doors

The work in food processing plants is a continuous struggle against time, the products must be delivered fresh and on time to the final consumer. The chillers and freezers must be tightly closed by the hygienic doors. However, there is a number of other, not refrigeration rooms, but not less important, e.g. production areas. It is not an absolute hygiene that matters here, but also reliable performance of the doors, often 24 hours a day. Jest as the hinged doors, the sliding industrial doors are made of the best materials, and their construction is adjusted to the intensive operation. For example, the most often used sliding rail is almost the same as the one, used in the heavier chiller doors. The construction of the doorframes is very similar, but a little bit narrower in fact, however, the insulation is made of the same dense polyurethane foam of the best quality.

technical characteristics

gallery

optional equipment

movies

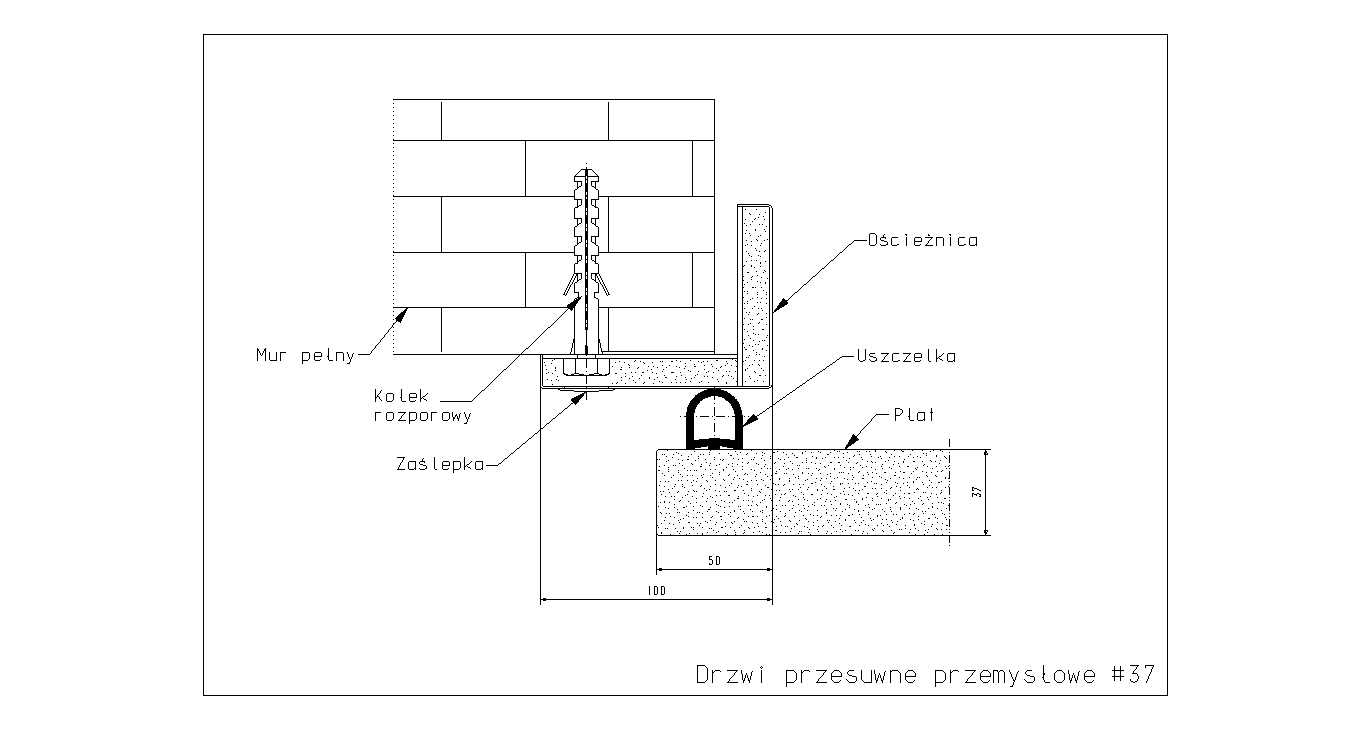

frames

Classical sliding rail

The classical sliding system is a standard rail. The construction, refined over time, is made entirely of stainless steel. The system cover of the door with the classical sliding rail is made of the same material as the door panel. The polyethylene rollers are specially designed to provide a quiet operation and the durability of the door.

technical characteristics

Pipe sliding rail

The pipe rail system consists of aesthetically brushed stainless steel pipe and two large, specifically profiled guide rollers. Due to the special profile of the rollers and the pipe, just as in the classical system, the door falls down and pushes to the doorframe, while closing.

technical characteristics

Sliding, double leaf doors

The industrial sliding double-leaf doors are the equivalent of the single-leaf doors, but this type of the doors is used in the wider door niches or wherever there is no enough space to use a single door panel. The double-leaf construction is also a practical solution for the doors for the tubular track. The sealing, installed between the door panels, absorbs the contact of the door leaves when closing at the same time.

technical characteristics

gallery

optional equipment

movies

frames

Classical sliding rail

Classical sliding rail - Standard system, refining over the years design, made entirely of stainless steel. Classical sliding rail has the cover made of the same material as the door leaf. Polyethylene rollers are specially designed to provide quiet operation and durability of the door. During closing the door go down and tighten the frame.

Pipe rail system

Pipe sliding rail is constructed of aesthetically brushed stainless steel pipe and two large especially shaped PE black rolls. Special shaping of the tube causes that the rollers fall down and tightened the frame during closing.

.jpg)

.jpg)

.jpg)